Simple Cutting Software X

version 2025.11.30.0

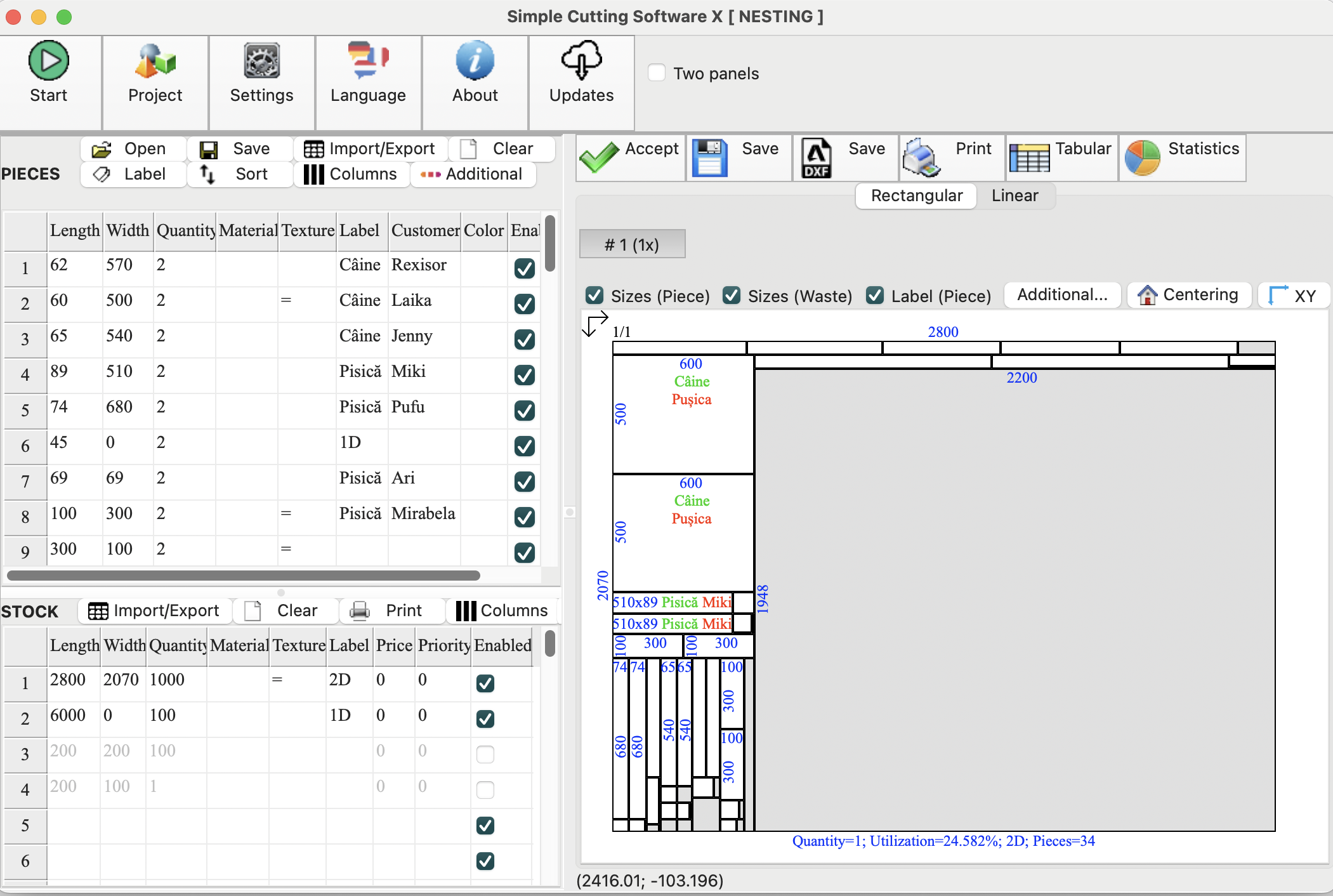

Cutting optimization software running on Windows, macOS / OS X and Linux.

|

How to install Videos How to use Features Price & Buy now What is new? Related software Contact us |

How to install Simple Cutting Software X

A trial version for 90 days is available.

Windows 64bit (7, 8, 10, 11)

-

With installer - will create shortcuts on Desktop and Programs.

Download scsx_win64_installer.exe (3.27 MB) or scsx_win64_installer.zip (3.25 MB).

or

-

Without installer

Download simple-cutting-software-x.exe (10.8 MB) or simple-cutting-software-x.zip (4 MB).

You may save it directly on Desktop.

Run it. There is no installation kit. Please remember where you saved it so that you can run it next time.

If you don't know what to choose, please download the installer.

Windows 32bit (7, 8, 10)

-

With installer - will create shortcuts on Desktop and Programs.

Download scsx_win32_installer.exe (2.96 MB) or scsx_win32_installer.zip (2.95 MB).

Apple macOS (High Sierra (10.13) or newer, Apple Silicon and Intel)

Download scsx_macos.zip (6 MB).

It is .zip archive. Double-click it in Finder. It should be decompressed in the same folder as the zip archive. The name of the application is Simple Cutting Software X.app. Move it in Application folder or run it directly from there.

Apple macOS / OS X (Yosemite (10.10), El Capitan (10.11), Sierra (10.12))

Download scsx_macos_old.zip (7.1 MB).

Linux Ubuntu (tested on Ubuntu 18 - 64bit)

Download simple-cutting-software-x.deb (3.33MB)

Install the program with Ubuntu Software Center.

You will find the program in the list of installed programs.

How to use Simple Cutting Software X

-

Pieces to be optimized (customer demand) are introduced in Parts table. You can also import them from Sketchup by using a special exporter from here.

-

Pieces to cut from (the sheets) are introduced in Stock.

-

Set some parameters by pressing button Settings.

-

Press Start button. At the end of cutting optimization the solution will be graphically displayed.

-

You may print and save it.

Frequently asked questions / comments

-

How can I enter more than 100 pieces in Parts or Stock? Answer: Select a cell in the last row of the table and press Bottom arrow.

-

How do I copy-paste data from from Excel? Answer Select the data from Excel and copy them to Clipboard. Then, in the optimization program, select the cell where the paste should begin. The cell where you paste must be selected and the cursor must NOT be visible. Press Ctrl+V (Command+V or MacOS) or right click and select the Paste command.

More movies

Simple Cutting Software X on Mac OSX

Manual arrange post optimization in Simple Cutting Software X on Mac OSX

Fractional values in Simple Cutting Software X

Exporting Sketchup models to Simple Cutting Software X

Simple Cutting Software X on Ubuntu Linux

Import data from CSV, TSV or TXT files

Copy/paste from/to Excel in Simple Cutting Software X with Ctrl+C and Ctrl+V. Also you can right click the tables and then choose the Copy-Paste commands from the displayed menu.

Fiber (grain) direction. If one specifies a direction for both sheets and parts, the program will rotate the parts in order to satisfy the fiber direction. If no direction is specified the parts will be freely rotated.

Copy/paste from/to Google Docs in Simple Cutting Software X. If you don't have Excel, you can use a free spreadsheet, namely Google Docs.

Working with priorities. 0 is the highest priority. Sheets with higher priority will be cut before sheets with a lower priority.

Printing adhesive labels in Simple Cutting Software X.

Hiding/showing columns (right click on table header) and sorting data in Simple Cutting Software X.

Printing rolls (long materials) with Simple Cutting Software X.

Features of the Simple Cutting Software X

-

2D Guillotine optimization - The cuts are performed from one side to the other of the material. This feature is very useful for glass, wood, thermo-glass, ...

-

Manual arrange after optimization - one can modify the layout by moving, adding and deleting pieces with the mouse.

-

Any measurement metric- The way in which you introduce the data is a general one. You don't have to specify a metric. Just choose a metric in your mind and enter all data using that metric only.

-

Fractional input - You may introduce data either real as 100.5 or fractional as 100 1/2. Precision for fractions can be set from menu Settings. Do not mix real values with decimal separator (".") with fractional values. Choose one style and stick with it.

-

Adjustable cutting blade thickness- For glass cutting with diamond the cutting blade thickness is 0, but for wood, metal handling you need a saw with a greater thickness.

-

Adjustable limit for breakable parts - No waste will have a size lower than this parameter and no 2 parallel cuts will be closer than this. It is used in order to avoid the breaking of too small material. Useful in glass industry.

-

Maximal cut length - it allows you to limit the length of the cuts that may be performed.

-

Adhesive labels - printing adhesive labels for each part.

-

Grouping of identical sheets - You can group/ungroup identical sheets with one click.

-

Grain direction control - useful for wood cutting optimisation. A parameter let the user to specify the grain for parts and stock.

-

Graphical display (black and white) of the obtained results - the results are displayed as images with text labels.

-

Save images - all the obtained 2D sheets can be saved as .png images with 1 click.

-

Grouping similar layouts - this will reduce the number of printed sheets of paper. The number of repetitions for each sheet will be displayed.

-

Printing the obtained layouts - on any printer.

-

XML Support. Loading and saving data (parts and stock) from/to *.xml.

-

Very fast running time - Solutions are obtained within seconds.

-

Win64 / MacOS native application. No dependencies required.

-

Single file application. You can move a single file to a new computer and it will run without installation.

-

Very efficient written. .exe has about 7 MB and the installation kit just over 2 MB.

-

Desktop application. You are in control of your data. You do not risk loosing data if some distant server fails. You can run the application without problems even if the internet is not working.

-

Interface in multiple languages.